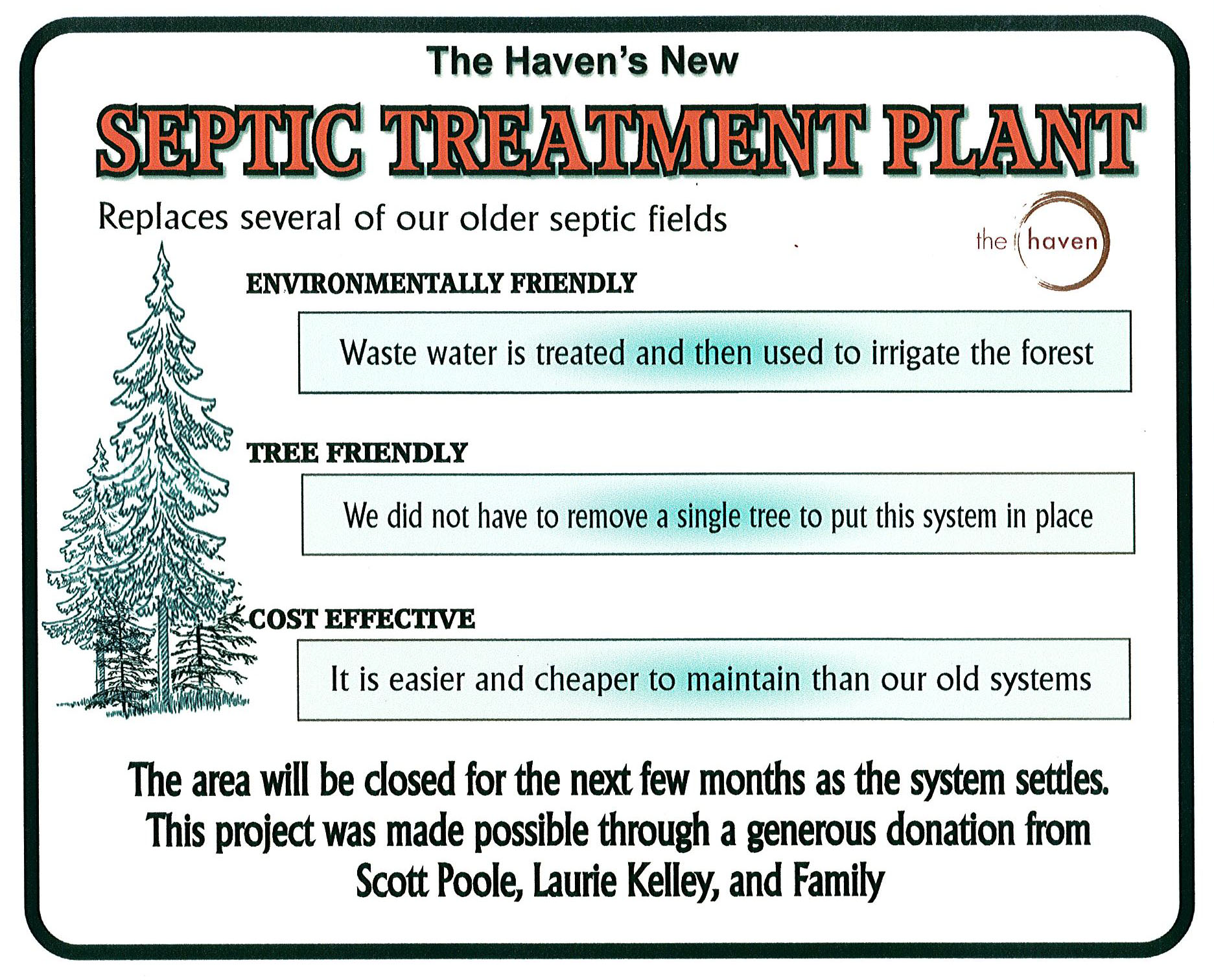

A new septic treatment plant for The Haven

By Rachel Davey

On your next visit to The Haven, you will see a new septic treatment plant on the edge of the forest opposite the Raven building. The need for this major new piece of infrastructure came from the discovery phase of the Facilities Masterplan. In the process of finding out everything we needed to know about the Haven property, we undertook an in depth study of our waste water system.

We all know that The Haven is a place where you can come and deal with your sh*t. It’s also vitally important that we effectively deal with literal sh*t as The Haven (and Gabriola) has never had a municipal sewerage system. We have many septic fields of different ages and types. The study revealed that two of them were coming to the end of their lifespan, and were now in the setback from the ocean. We undertook this project in order to solve these two problems by consolidating a number of systems into one and replacing the failing fields. In addition, we wanted to honour one of Ben and Jock’s original guiding principles for The Haven, namely to preserve as many trees as possible and “operate with love, integrity and respect for … our environment” (from The Haven’s mission statement).

The work was undertaken through December, for the most part using local businesses, as is our preference. It is now complete, and we are very happy to announce that it is:

- Environmentally friendly: waste water is treated and then used to irrigate the forest (see below for more information on this.

- Tree friendly: we did not have to remove a single tree to put this system in place.

- Cost effective: it’s easier and cheaper to maintain than our old systems.

None of this would have been possible without the generous support of Scott Poole, Laurie Kelley and family. They provided financial support that covered nearly 90% of the cost of the project. They have been instrumental in providing guidance and inspiration for so many innovations at The Haven, including the organic garden. In keeping with The Haven’s tradition of using names of birds, we will name this important new piece of our infrastructure after their family’s favourite bird: it will be called the Hummingbird Septic Treatment Plant. For the next few months the system will be settling, so that area of the property will be closed off, and you are most welcome to check it out the next time you are walking around Crystal Lane.

The view of the treatment plant from the top of the Raven building.

For those of you who are interested, here is some more information about the system that we used. It is a Quality Bio-Rock system and very environmentally friendly.

The Quality Bio-Rock unit is a passive attached media system that uses no mechanical or electrical parts (except for the very small pump to move the effluent from one chamber to a different tank after treatment, specific and custom to this unit). It utilizes natural venting for air flow and exchange. It is this air exchange that allows the aerobic bacteria living on the media to ‘do its stuff’ and clean up the filtered raw sewage to near drinking-water standards. Since there are no actual parts in the treatment plant the maintenance requirements are minimal: no blowers or aerators to change or fix, and no contaminated media to replace. The system functions as a two stage treatment system. Initially the raw sewage enters a primary tank to provide separation and the breakdown of organic solids (Primary Treatment). The sewage then passes through an effluent filter before discharging into the Bio-Rock unit which incorporates the well proven aerobic digestion process (Secondary Treatment).

In traditional activated sludge systems, aerators and/or agitators pump air 12-24 hours per day to provide enough oxygen, so that a limited range of organisms can survive to break down the waste. The Bio-Rock units work without any electrical or mechanical aerators: they simply require natural air draft for aeration. In a mechanical system machinery works hard and is energy-intensive with a high carbon footprint. Activated sludge is using excessive amounts of fossil fuels in the form of electricity for operating and sludge digestion. The Bio-Rock units have a very low carbon footprint. In Europe, the Bio-rock system is used to drain directly into watercourses and lakes.